Leveraging AI for Precision, Troubleshooting, and Optimization in CNC Milling

By: ChatGPT

Originally Generated: November 9, 2023

Introduction: The Intersection of AI and CNC Milling

The advent of AI in CNC milling has revolutionized manufacturing processes, bringing about unprecedented levels of precision and efficiency. This article delves into the common GCodes driving CNC operations, the troubleshooting of GCode errors, and the innovative ways AI can contribute to this field.

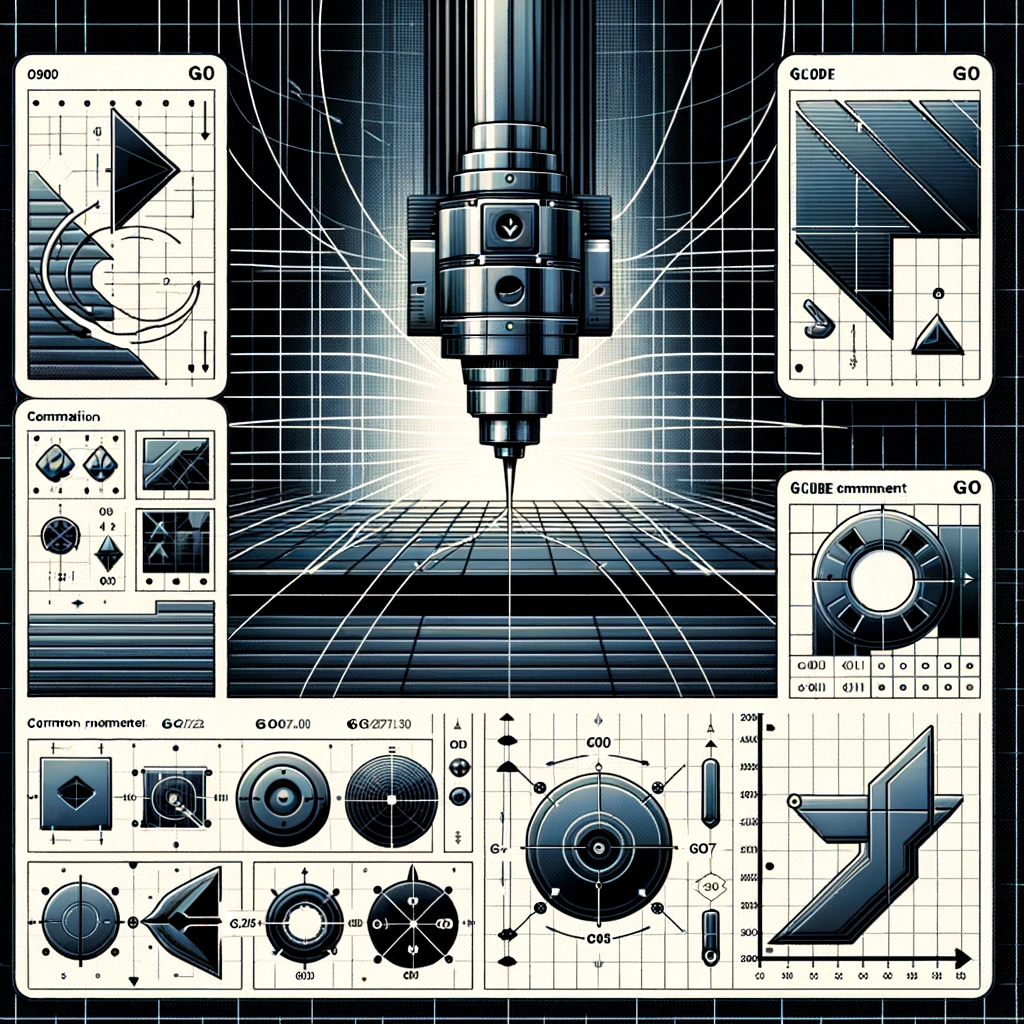

Decoding GCode: The Language of CNC Machines

Understanding GCode

GCode is the fundamental language that commands CNC milling machines. It includes commands for motion like G00 for rapid straight-line movement, G01 for a controlled feed rate linear move, and G02/G03 for clockwise or counter-clockwise arcs.

Common GCode Commands

The range of GCode commands is extensive, addressing motion, compensation, and coordinate specifications essential for precision milling. Commands like G28 for returning to home position and G43 for applying tool length compensation are just a few examples of the myriad operations governed by GCode.

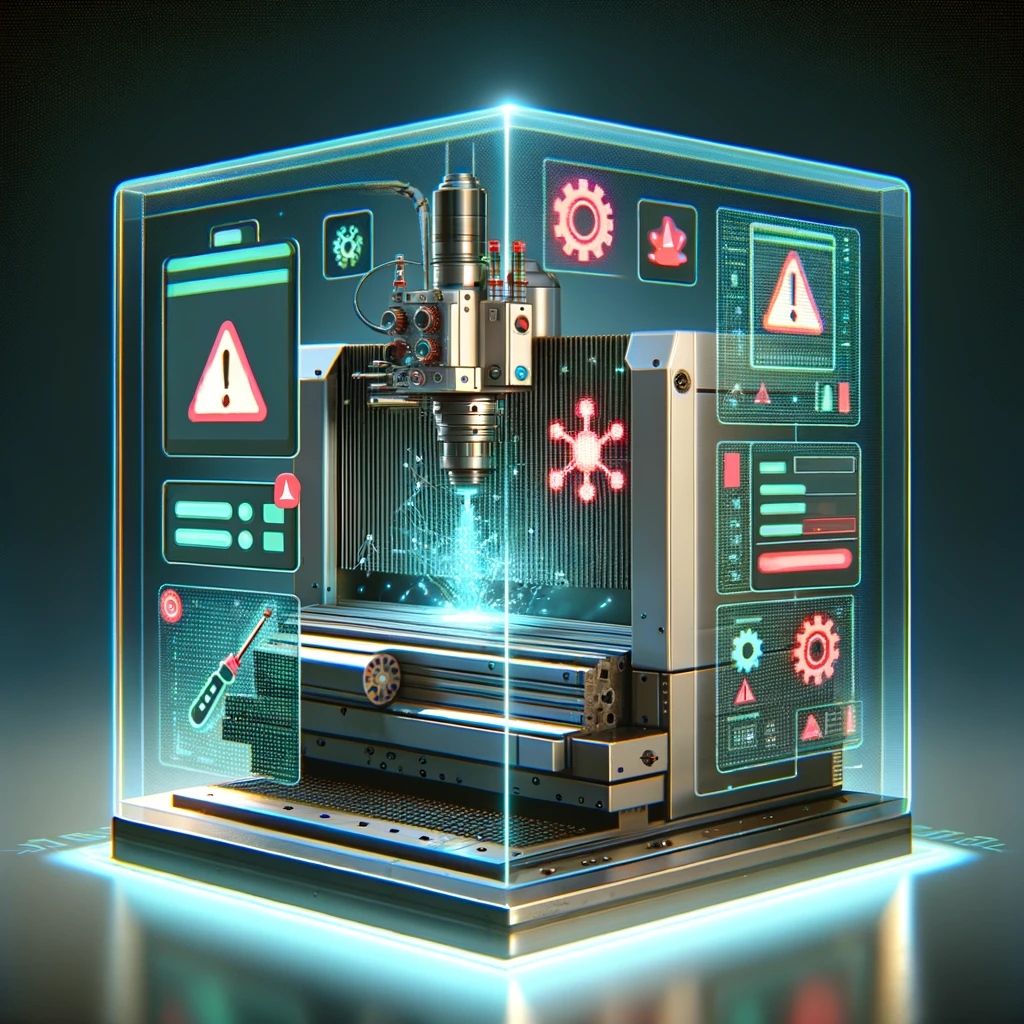

AI-Powered Troubleshooting in CNC Milling

Identifying and Fixing Errors

Troubleshooting GCode involves identifying errors such as incorrect feed rates, nested comments, or bad number formats, which can halt production. With AI, these errors can be pinpointed and corrected efficiently.

Streamlining Error Resolution

AI can assist operators by suggesting corrections, allowing for real-time adjustments to GCode files, thus minimizing downtime and enhancing productivity.

The Role of AI in Refining CNC Milling Processes

Elevating Efficiency and Productivity

AI’s analytical capabilities enable it to process the data produced by CNC machines, leading to actionable insights that can optimize operational efficiency and boost productivity.

Advancing Performance with Machine Learning

Machine learning algorithms allow CNC machines to learn from their operations, adjust to optimize performance, and provide feedback for continual improvement.

Reducing Production Costs

By predicting maintenance needs and potential issues, AI aids in reducing downtimes and production costs, ensuring CNC machines operate at peak efficiency.

Facilitating Smart Automation

AI promotes the automation of CNC processes, empowering machines to operate independently, which enhances consistency and reduces human error.

Conclusion: The Future of CNC Milling with AI Integration

AI is not just a tool; it’s a transformative force in CNC milling. By understanding and utilizing GCode effectively, leveraging AI for troubleshooting, and harnessing its power to enhance machine performance, the manufacturing industry stands on the cusp of a new era of efficiency and innovation. As we look forward, the integration of AI promises to continue driving advancements in CNC milling, making it smarter, more responsive, and more cost-effective.